Homepage >> Products >> WDW Electronic Thermal Insulating Material Testing Machine

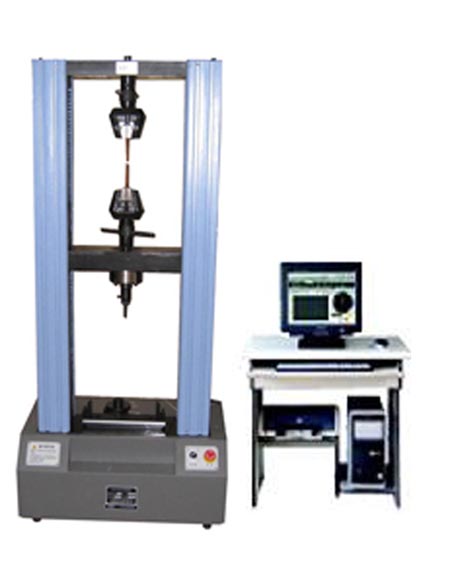

WDW Electronic Thermal Insulating Material Testing Machine

Ⅰ.Standards & application:

This machine satify: GB/T16491-2008 Electronic Universal Testing Machine and JJG-1986 Verification Regulation of Electronic Universal Testing Machine; also comply with test requirements in GB, ISO, ASTM, JIS etc. It can automatically get upper yield force, lower yield force, non-proportional extension strength, total extension strength, tensile strength, elastic modulus, extension under max. force and other mechanical property indexes.

Application range: it accords with mechanical test requirements as compression, tension, bond strength and shearing strength in GB8813-88 Compression Test Method for Rigid Foamed Plastics, GB8812-88 Bending Test Method for Rigid Foamed Plastics, JC-T547-2005 Cementing Compound for Ceramic Wall and Floor Tiles, JG149-2003 Expanding Polystyrene Panel Plastered Outer Wall Heat Insulating System, JC623 Insulated Board Steel Mesh, Alkali Proof Fiberglass Mesh etc.

Ⅱ.Function:

1.main machine:

- Portal frame structure, shell is sprayed with plastics, with nice appearance.

- Screw can only bear tensile, so it can prolong its life service and rigidity.

- Precise screw assembly loading, two nuts tightened to ensure zero clearance and high rigidity and high dynamic property.

2.AC servo speed speeding loading system

- Using Japanese AC servo motor and driver, imported German planetary wheel speed reducer, which is specially equipped with servo motor, connected directly with motor, with characteristics of small volumn, high efficient, low noise, high rigidity, high acceloration, high reliablity.

- AC servo motor has speed ratio up to 50000 times, which ensure the crossbeam stepless adjustable with speed of 0.01-500mm/min, it has perfect overcurrent and overvoltage protection function, embeded with accelaration -decelaration mode, smoothly switching.

3.Control system with built-in full hardware

- embeded full digital electric control technique: completely realizing constant speed control to displacement, test force, strain, perfect control property, full digital hardware realization mode, strong anti-interference capability, good stability.

- Software with high integration, which is applicable to various test requirements for insulated materials.

Ⅲ.Basic configuration:

|

Name |

Function |

Qty. |

Remarks |

|

Main machine frame |

Portal frame structure

Precise screw assembly

High prexision load sensor

Adjustable limit position device

Perfect screw protection cover |

1 set

2 sets

1 pc. |

Self-made |

|

Embeded full digital controller |

Embeded sensor signal conditioning

A/D converting circuit

Servo drive signal generator

Overvoltage protection circuit

Display drive circuit

Complete function software |

1 set |

Self-made |

|

Drive device |

AC servo motor and driver

Precise planetary speed reducer |

1 set |

Japan

German |

|

Test accessories |

Special accessories for heat insulated materials |

1 set |

optional |

|

Compression accessories |

1 set |

|

Motor shearing grips |

1 set |

|

Mesh tensile grips |

1 set |

|

Extensometer |

|

1 set |

optional |

|

Computer |

|

1 set |

|

|

Printer |

|

1 set |

|

|

software |

Special software for testing machine, comply with test requirements in GB/T228-2002 Test Method for Metal At Room Temperature; GB/T8813-88 Test Method of Compression Property for Outer Wall Heat Insulating Materials; JGJ Technical Criterion for Outer Wall Heat Insulting Engneering; JC/T992-2006 etc. |

|